Publications

C. Robeller, N. von Haaren

in Journal of the International Association for Shell and Spatial Structures, 61(2)

[Tsuboi Award for the best Journal Paper of the IASS in 2020] The article describes a new construction system for shell structures made from door- and window cut-offs resulting from cross laminated timber (CLT) production lines. For the first time, form-fitting fasteners made of beech laminated veneer lumber are used in a shell made of engineered wood plates, enabling a particularly simple, fast and precise construction. The efficient planning and production of a multitude of differently shaped elements is made possible by a CAD plug-in developed by the authors. The article presents the general application possibilities and limitations of the system, as well as the case study of a shell demonstrator with a span of 12 meters, built from 229 hexagonal plates. A detailed structural analysis is presented for the demonstrator, including an experimental load test to confirm the FEM results.

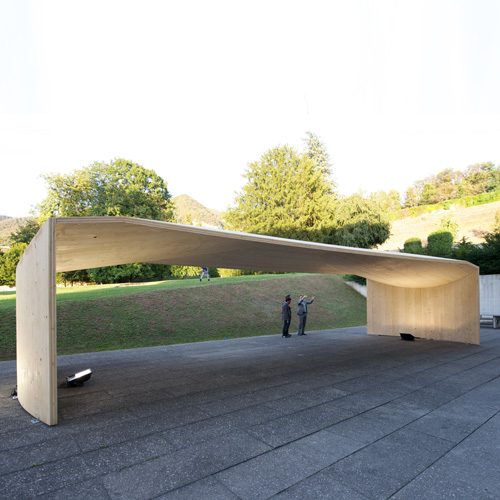

Robeller, C. Barata, E., Tagliaboschi, V. and Schmidt-Kleepsies, F.

in Proceedings of the IASS 2020/21 Annual Symposium

[Best Paper Award at the IASS 2021 Conference in Surrey] The HexBox Canopy demonstrates a new “plug & play” system for the rapid on-site assembly and disassembly without formwork of a segmented timber shell, consisting of relatively inexpensive, prefabricated hexagon-shaped boxes made from plywood plates. With 1531 timber segments making up 201 boxes, the HexBox shell is made exclusively of plywood components without the addition of any kind of metal fasteners for the main load-bearing structure. The major novelty is the wood-only connections between the box components, which are produced from cut-off waste material resulting from the cutting of the main plates of the structure. These connectors are inspired by traditional wedge joints, which were a smart and common method in handcrafted carpentry and cabinetmaking. Rather than attempting ultra-precisely fabricated elements, the wedges allow assembling box-like segments even when there are small imprecisions. Additionally, these joints allow for pulling and forcing the boxes together, closing gaps between the elements which may occur during assembly. Another key aspect is the introduction of an innovative technique that allows for the simple and safe 1K PUR adhesive joining of thousands of miter joints with individual dihedral angles. Conventional clamping tools are indeed designed for orthogonal miter joints and could therefore not be used here..

C. Robeller, V. Viezens

in 24th International Timber Construction Forum IHF 2018

The article describes a new construction system for shell structures made of cross laminated timber (CLT). For the first time, form-fitting fasteners made of beech laminated veneer lumber are used in a shell made of engineered wood plates, enabling a particularly simple, fast and precise construction. The efficient planning and production of a multitude of differently shaped elements is made possible by a CAD plug-in developed by the authors. The article presents the general application possibilities and limitations of the system, as well as two case studies: a first realized construction for a fair booth and the structural investigation of a dome with a span of 15 meters.

C. Robeller, V. Helm, A. Thoma, M. Kohler, F. Gramazio, Y. Weinand

in FABRICATE 2017

Integral joints provide a rapid, simple and mechanically strong connection between parts. Our investigation focuses on the assembly of cross-laminated wood veneer plates, where previous studies have shown that the strength of through-tenons is equivalent or superior to state-of-the-art fasteners such as screws or nails. This mechanical behaviour is highly dependent on a precise fit of the joints, where no gaps are left between the parts. However, the manual assembly of such tight-fitting joints can be complicated. Thanks to its rectangular cross-section, a single through-tenon joint is a sufficient assembly guide for an entire plate, but multiple through-tenons are required to establish a mechanically strong connection.

C. Robeller, Y. Weinand

in TEC21 Schweizerische Bauzeitung

Der neue Holzbau für einen Theatersaal in Vidy nimmt derzeit Gestalt an. Er liegt neben dem Theater, das Max Bill als Provisorium für die Expo 64, die Landesausstellung von 1964, entwarf (Situationsplan rechte Seite oben). Als Ersatz für den provisorischen Zeltbau wünschte die Bauherrschaft eine repräsentative, gedämmte und akustisch vorteilhaftere Spielstätte. Sie sollte ausserdem zu dem bestehenden Kubus von Max Bill passen, sich aber in Form und Material davon unterscheiden. Das durch das Institut du bois (IBOIS) sowie den Architekten des Atelier Cube erarbeitete Projekt, ein rasch zu erstellendes Faltwerk aus Holz als innovative architektonische Struktur, umweltfreundlich und zerlegbar, stiess auf Interesse.

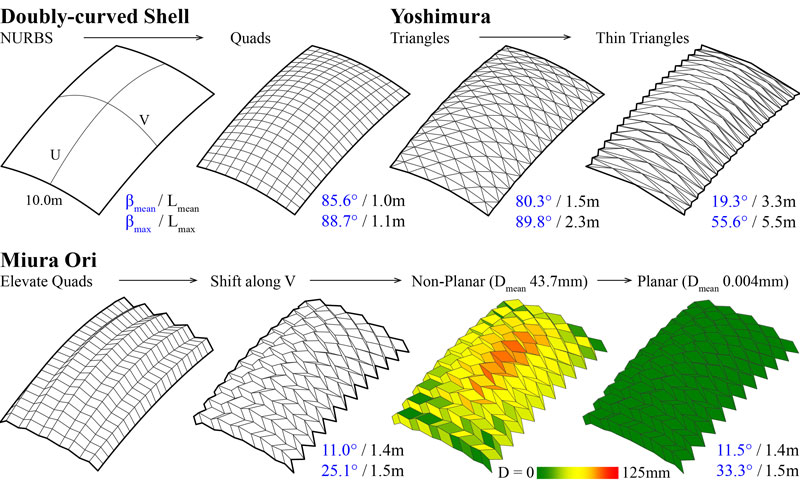

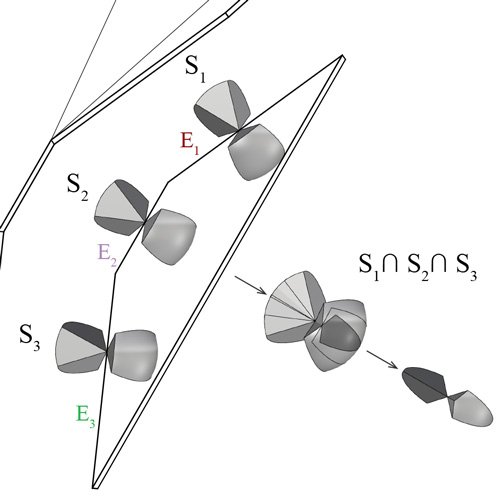

C. Robeller, M. Konakovic, M. Dedijer, M. Pauly, Y. Weinand

in Advances in Architectural Geometry 2016

This paper presents a new lightweight construction system for doubly-curved shells, built from two interconnected layers of structural wood veneer plates. The system uses integral through-tenon joints for a fast, precise, and simple assembly, allowing for the construction of a series of differently shaped shells without a costly mould or support structure. Instead, inclined joints cut with a 5-axis CNC milling machine embed the correct location and angle between plates into the shape of the parts. This constrains the relative motions between joined parts to one assembly path. To take advantage of the benefits of such connectors, the constrained assembly paths must be considered in the fundamental design of the system, allowing for the insertion of each plate. This imposes additional constraints in the segmentation process of doubly-curved shells. In order to meet the requirements and resolve the multi-constraint system, we use a global, nonlinear optimization approach. Developed as a close collaboration between architects, computer scientists and structural engineers, the paper includes an experimental analysis of the influence of parametric modifications in the shape of connectors on their load-bearing performance.

C. Robeller and Y. Weinand

in Robotic Fabrication in Architecture 2016, p. 166-177, Springer Verlag, 2016

Integral attachment, the joining of parts through their form rather than additional connectors or adhesives, is a common technique in many industry sectors. Following a renaissance of integral joints for timber frame structures, recent research investigates techniques for the attachment of timber plate structures. This paper introduces double through tenon joints, which allow for the rapid, precise and fully integral assembly of doubly-curved folded surface structures with two interconnected layers of cross-laminated engineered wood panels. The shape of the plates and the assembly sequence allow for an attachment without additional connectors or adhesives. The fabrication and assembly constraint based design is achieved through algorithms, which automatically generate the geometry of the parts and the G-Code for the fabrication. We present the fabrication and assembly of prototypes fabricated with 3D CNC milling and laser cutting systems, comparing and discussing the advantages and disadvantages of the individual techniques.

C. Robeller, Y. Weinand

in International Journal of Space Structures

Automatic joinery has become a common technique for the jointing of beams in timber framing and roofing. It has revived traditional, integrated joints such as mortise and tenon connections. Similarly, but only recently, the automatic fabri- cation of traditional cabinetmaking joints has been introduced for the assembly of timber panel shell structures. First prototypes have used such integrated joints for the alignment and assembly of components, while additional adhesive bonding was used for the load-bearing connection. However, glued joints cannot be assembled on site, which results in several design constraints. In this paper, we propose the use of dovetail joints without adhesive bonding, on the case study of a timber folded plate structure. Through their single-degree-of- freedom (1DOF) geometry, these joints block the relative movement of two parts in all but one direction. This presents the opportunity for an interlocking connection of plates, as well as a challenge for the assembly of folded plate shells, where multiple non-parallel edges per plate must be jointed simultaneously.

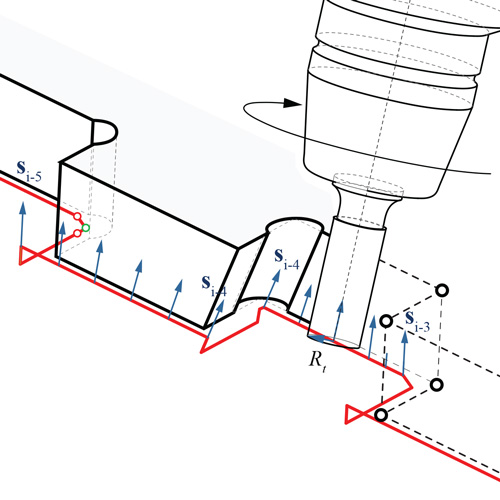

C. Robeller and Y. Weinand

in Proceedings of the World Conference of Timber Engineering WCTE 2016

Integral Mechanical Attachment (IMA) uses features in the form of components for their connection. In addition to the transfer of forces, locator features are used as integral assembly guides. Prismatic, single-degree-of-freedom (1DOF) joints only allow for a single assembly motion and therefore a simple, rapid and precise assembly. In modern timber construction, such CNC-fabricated 1DOF joints are commonly used in frame structures. Recent research is investigating the application of similar techniques for the joining of timber plate components, inspired by traditional handcrafted joints from cabinetmaking. The method presented in this paper builds upon previous research, allowing for new geometric variations such as non-orthogonal 1DOF plate joints and a simplified cutting process using a 5-axis simultaneous cutting technique. In addition to the use of milling tools, the method is compatible with 5-axis laser cutting and 5-axis waterjet cutting. Advantages and disadvantages of the different methods are being discussed.

P. Mayencourt, C. Loraux, C. Robeller, E. Brühwiler and Y. Weinand

in IABSE Conference - Structural Engineering, September 23-25 2015, Geneva, Switzerland

Folded plate structures or shells are statically efficient structures. However, their construction is limited by the complexity and cost of their formwork. We used Computer Numerical Control Milling Technology to design a wooden formwork for an Ultra-High Performance Fibre Reinforced cement-based Composite (UHPFRC) folded plate arch. This paper describes the design and assembly of a formwork made from cross-laminated veneer lumber panels (LVL) with integrated wood-wood connections and the testing of the resulting thin origami-like UHPFRC arch. Currently achieved for a lab scale, CNC wood milling technology combined with integrated panel joints could enable mass-customized formwork for complex structures. UHPFRC is probably the only existing material with required strength and sustainability properties for ultra-thin structures. However, special attention should be given to the casting direction and fibres orientation in sharp edges. Based on this consideration and the result of the first lab test, some geometric adjustments and construction details are proposed and discussed in this paper.

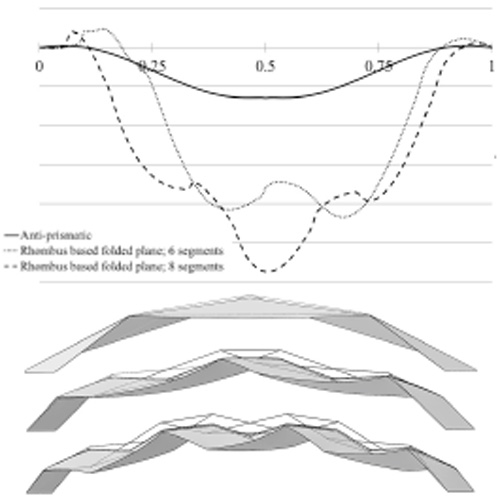

A. Stitic, C. Robeller and Y. Weinand

in IABSE Symposium Report, IABSE Conference Nara, 2015: Elegance in Structures, pp. 1-8(8)

This paper analyses the potential of different possible folded form topologies for generating timber folded surface structures. The main advantage of such structures lies primarily in the realm of ecology and sustainability. By offering an integral way of construction, which fulfils both a supporting as well as a covering function, very lightweight structures are achieved. Also, a greater degree of prefabrication is possible which leads to a reduced overall cost. As these structures consist of a large number of discrete, thin plane elements, proper edgewise connection details are needed in order to ensure an efficient load bearing system. For structures made of wood products this presents a great challenge using the state-of-the art joining techniques. For this reason, the use of timber folded plate structures in civil engineering applications has been very limited. However, recently new technical solutions have been proposed for efficient edgewise joining of thin timber panels. In this paper focus is put on integrated mechanical attachment technique which utilizes digital prefabrication to integrate connectors through panel geometry. Considering the material and the chosen connection detail fabrication as well as assembly related constraints, feasible folded forms for folded surface structures are explored. Their influence on structural performance is studied and different forms are compared by means of Finite Element Analysis. Furthermore, based on the obtained results, form improvements are proposed and observations made on a case study of a built prototype structure are presented.

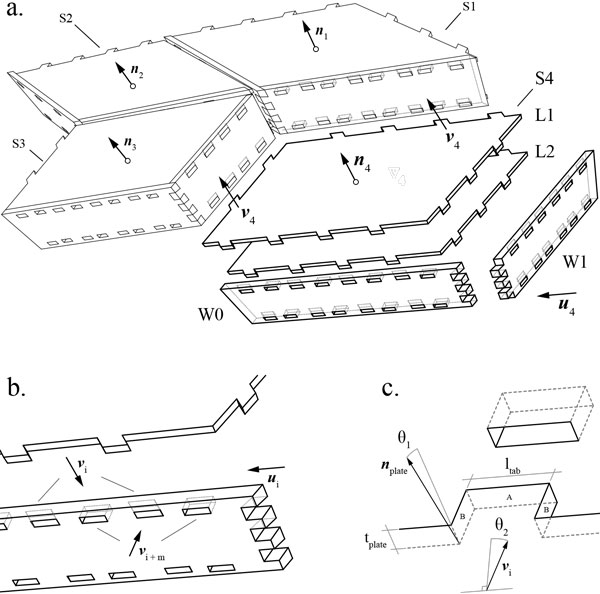

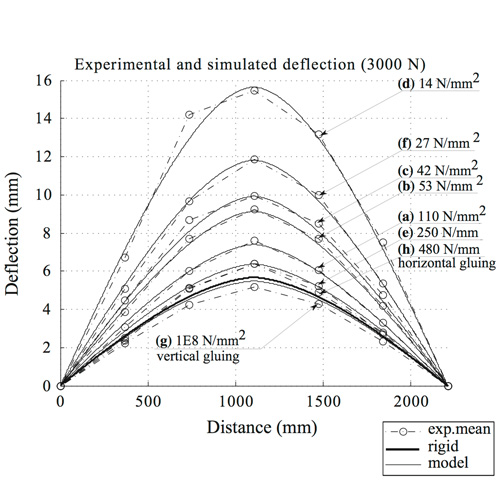

S. Roche, C. Robeller, L. Humbert, Y. Weinand

in European Journal of Wood and Wood Products, p. 1-9, Springer Verlag, 2015

This paper focuses on multiple tab-and-slot joints (MTSJ) for load-carrying assembly of structural wood elements, which are inspired by traditional cabinetmaking joints and adapted for automatic fabrication and engineered wood panels such as laminated veneer lumber. First a numerical method is presented for the estimation of the connections’ semi-rigid properties based on box beam samples. In a simplified model, the mechanical behavior of the joint is represented by potential elastic slips at interfaces. They are handled by the model with the help of rigidity modulus, which is determined by matching simulated and experimental deflections. Finally, the influence of tab length and contact face angle on the semi-rigidity of the joint is discussed considering a dovetail geometry of the MTSJ. Glued and screwed samples serve as references in this study.

C. Robeller and Y. Weinand

EPFL Doctoral Thesis No. 6564

Timber folded plate Structures combine the advantages of timber as a construction material, such as its carbon-dioxide storage, low energy production and favorable weight-to-strength ratio, with the structural efficiency and elegance of folded surface structures. The construction of such surface-active structure systems with timber is a relatively new development, driven by an increasing awareness for sustainable building constructions, and enabled by new engineered wood products. However, these constructions require a large amount of edgewise joints between the thin timber plates, which are difficult to address with state-of-the-art connection techniques. Instead of using mass-produced mechanical fasteners for these connections, this thesis investigates the use of customized Integral Mechanical Attachment techniques, which use geometrical features of the parts to establish connections, rather than additional fasteners. Integral joints were common in traditional woodworking, but their manual crafting became infeasible during the industrialization.

Computer-controlled fabrication technology, which is already available in the timber prefabrication industry, allows for an efficient, automatic production of integral joints. The advantages of such joints have already been demonstrated in framing constructions, where timber beams are used as the primary structural components. The proliferation of automatic joinery machines has repatriated customizable single-degree-of-freedom (1DOF) joints, which allow for the fast and precise assembly of prefabricated components. The objective of this thesis is to transfer these advantages to the construction of timber folded plate structures. Inspiration is taken from traditional cabinetmaking joints from Europe and Asia, as well as other industry sectors, where mass-produced integral joints are commonly used.

Jury: Prof. M. Fröhlich (president), Prof. Y. Weinand (directeur), J. Hakkarainen, Prof. M. Kohler, Prof. M. Pauly (rapporteurs)

C. Robeller, B. Hahn, P. Mayencourt, Y. Weinand

in Bauingenieur vol. 89, p. 487-490, Springer VDI Verlag, 2014

Die weit verbreitete automatisierte Vorfertigung im Holzbau, sowie moderne CAD-Software mit Programmierschnittstellen ermöglichen und vereinfachen zunehmend die Herstellung von komplexen Bauteilgeometrien. Diese Entwicklung erfordert und ermöglicht gleichermaßen auch Anpassungen und Neuentwicklungen der Verbindungstechnik. Analog zu den Entwicklungen im Holzrahmenbau, demonstriert die hier vorgestellte prototypische Schalenkonstruktion aus gekrümmtem Brettsperrholz die Adaption einer klassischen Holz-Holz Zinkungsstechnik aus dem Tischlerhandwerk, die mithilfe eines Industrieroboters automatisch hergestellt werden kann. Diese ästhetisch anspruchsvolle, sichtbare Verbindung ermöglicht eine tragfähige geklebte Verbindung und vereinfacht die Fügung der Bauteile durch eine integrierte Positionierlehre.

C. Robeller and Y. Weinand

in ACADIA 2014 Design Agency, p. 189-198

This paper presents our reserach into the design and potential applications of CNC fabricated snap-fit joints for cross-laminated veneer lumber panels (LVL). These joints are new to the building construction sector, but commonly used in other domains such as the automotive or consumer electronics industry. We explain our application of existing knowledge about the design and dimensioning of such joints, as well as several adaptations that we have made in order to optimize the connectors for the jointing of structural wood panels. This was necessary due to the materials and fabrication processes in timber construction, which are different from those in the sectors of origin of the snap-fit joints. We propose applications, including two case studies with physical prototypes.

C. Robeller, S. S. Nabaei, Y. Weinand

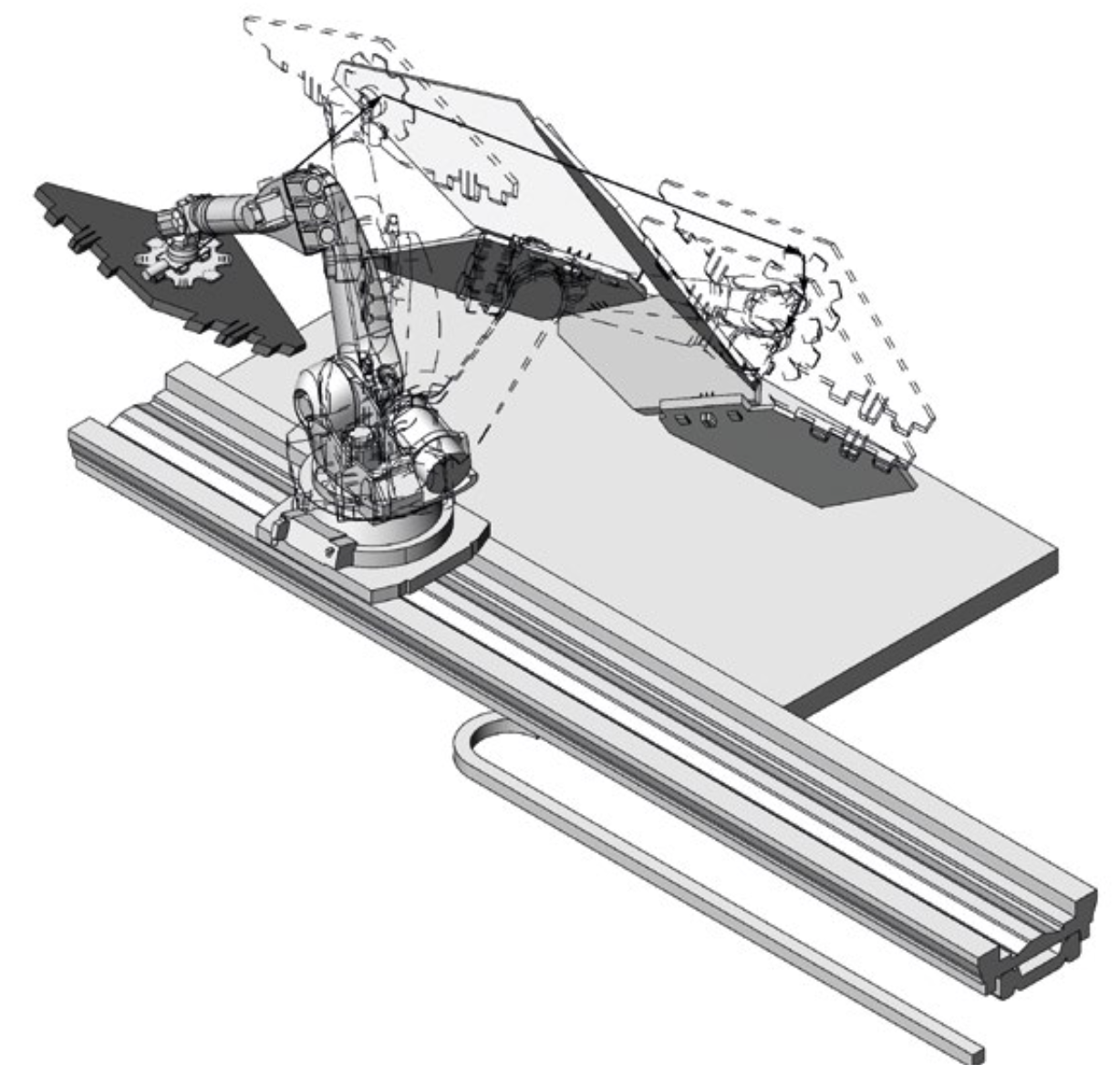

in Robotic Fabrication in Architecture 2014, p. 67-81, Springer Verlag, 2014

The prototype presented in this chapter utilizes the technique of curved folding for the design of a thin-shell structure built from curved cross-laminated timber panels (CLT). The curved-folded geometry allows for a span of 13.5 m, at a shell thickness of only 77 mm. The construction requires curved line CLT joints, which are difficult to address with state-of-the-art jointing techniques for CLT. Inspired by traditional woodworking joinery, we have designed connections for the integrated attachment of curved CLT panels, utilizing digital geometry processing tools to combine the advantages of traditional joinery techniques with those of modern automation technology.